Moll 3D: The Company That Uses Coffee Waste for 3D Printing

By Ruta N -During the pandemic, which marked a turning point in many lives, Juan Guillermo Molina, an electromechanical technologist by profession, faced unemployment. Instead of succumbing to circumstances, he invested in a 3D printer, never imagining that this machine would lead him to create what is now his life’s project: Moll 3D, a company dedicated to 3D printing plant pots using organic filaments, primarily derived from coffee.

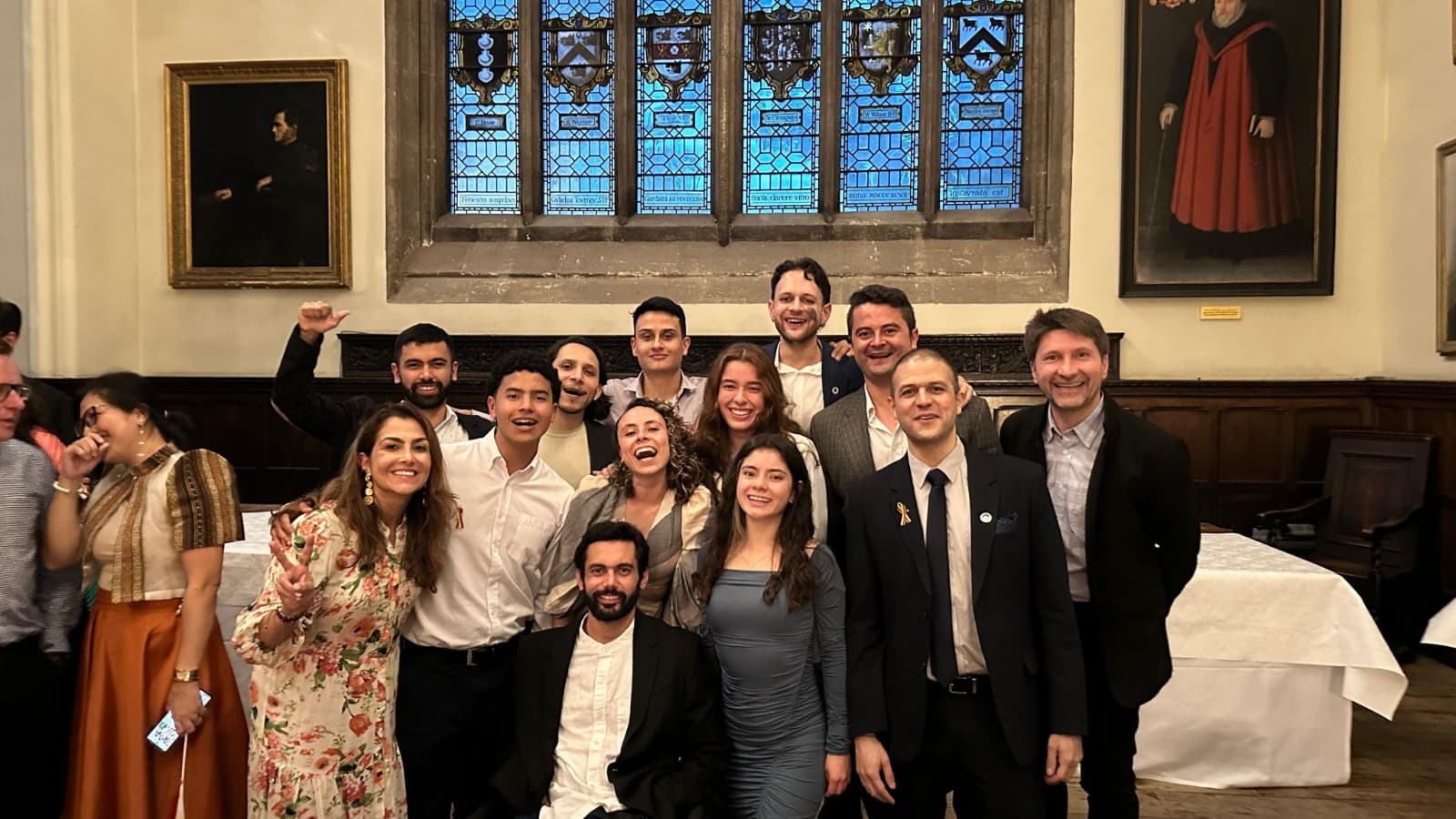

The success has been remarkable; recently, at the Entrepreneurship Night held at Ruta N, Juan Guillermo and his partner received the award for Entrepreneur of the Year.

History

With a decade of experience in restaurant maintenance, Juan Guillermo decided to explore the world of 3D printing during the lockdown. "I started printing and fell in love with 3D printing, making beautiful items like pots and lamps, and I started selling them," he shared during the interview.

During his exploration and sale of creations, he partnered with a former colleague, who was also his previous boss. Together, they decided to go beyond traditional prints and sought an innovative material, inspired by European trends in building with cement and glass. They turned to a local resource: coffee.

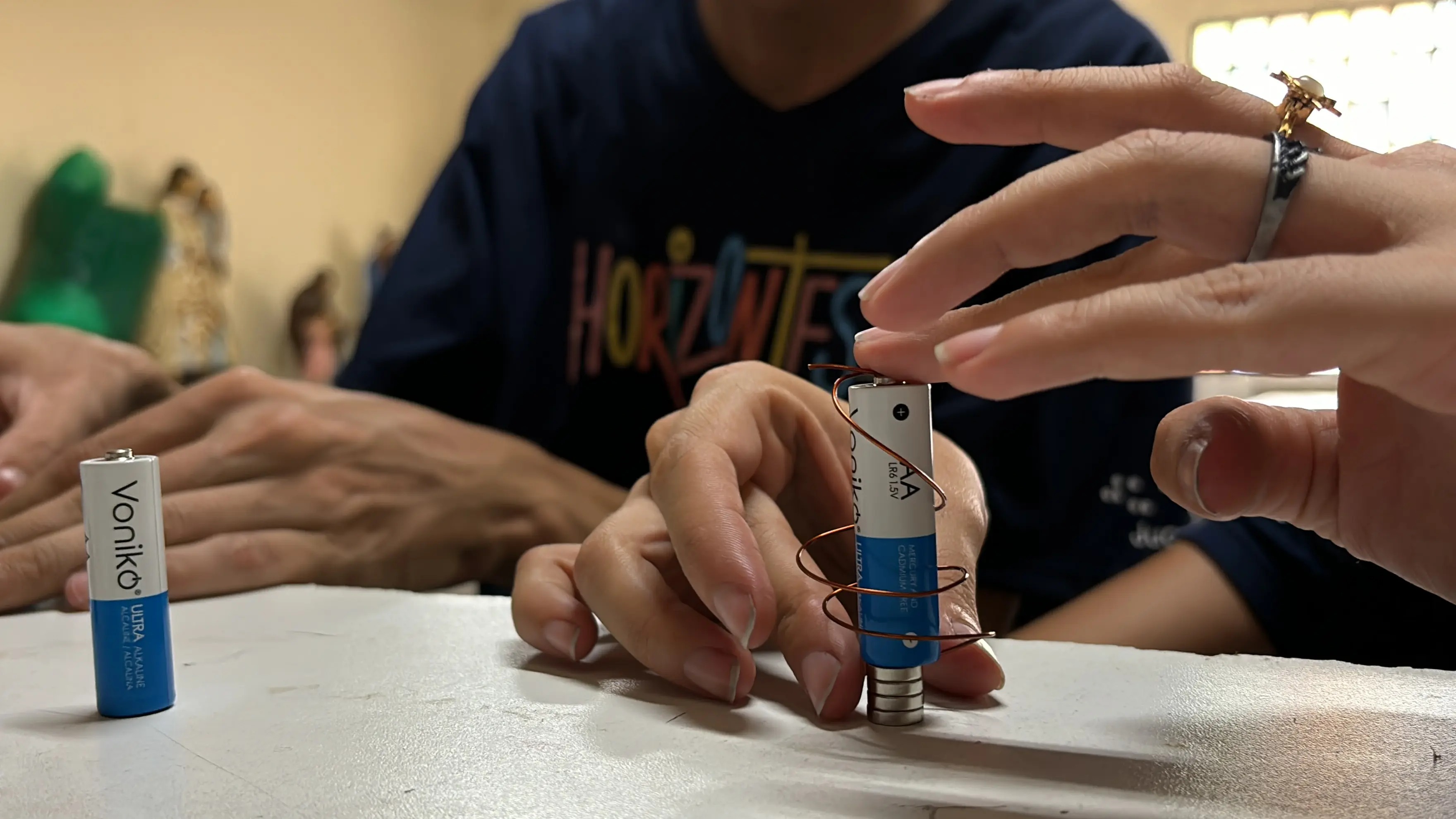

"I’m the son of a coffee grower; my grandfather is a coffee grower, so I was born and raised on a coffee farm," Molina explained. This personal connection led to the idea of using coffee grounds left over after brewing, known as borra, to create a 3D printing filament. Using a homemade extruder, they transform coffee grounds into usable filament for 3D printing.

The resulting filament, known as PLA (polylactic acid), is a thermocompostable, environmentally friendly plastic sourced from sugar cane, corn starch, or beets. Moll 3D developed a formula to repurpose coffee grounds, converting them into a base material for 3D printing.

Their first product was a pot made from this coffee filament, aiming not only to create aesthetically pleasing objects but also sustainable items with a strong environmental message.

The Boost from Ruta N

The opportunity to elevate their business arrived through Ruta N's Social Entrepreneurship project. Juan Guillermo shared how everything aligned at the right moment, and Ruta N’s incubator provided the necessary support to advance the project. “They helped us significantly and saw great potential in the business,” Molina noted.

Since Moll 3D started in June 2020, it has evolved substantially. Currently, it’s in the incubation process with Ruta N and the Innovation Lab, aiming to expand production capacity through a more advanced extruder. This investment would allow Moll 3D to increase both the efficiency and quality of its products.

The coffee pot has inspired Molina and his partner to explore creating filaments from other waste materials, like avocado skins. “The idea is to use organic materials that are typically discarded to create high-end design pieces for home decor.” Their approach combines pleasing aesthetics with a commitment to sustainability and a circular economy.

Although Moll 3D is still growing, Juan Guillermo remains grounded in his roots and original purpose: to transform waste into sustainable works of art. Looking to the future, he and his partner hope Moll 3D will become a regional brand known for sustainable home goods with a unique touch derived from organic and local materials.

By: Mateo Yepes Serna